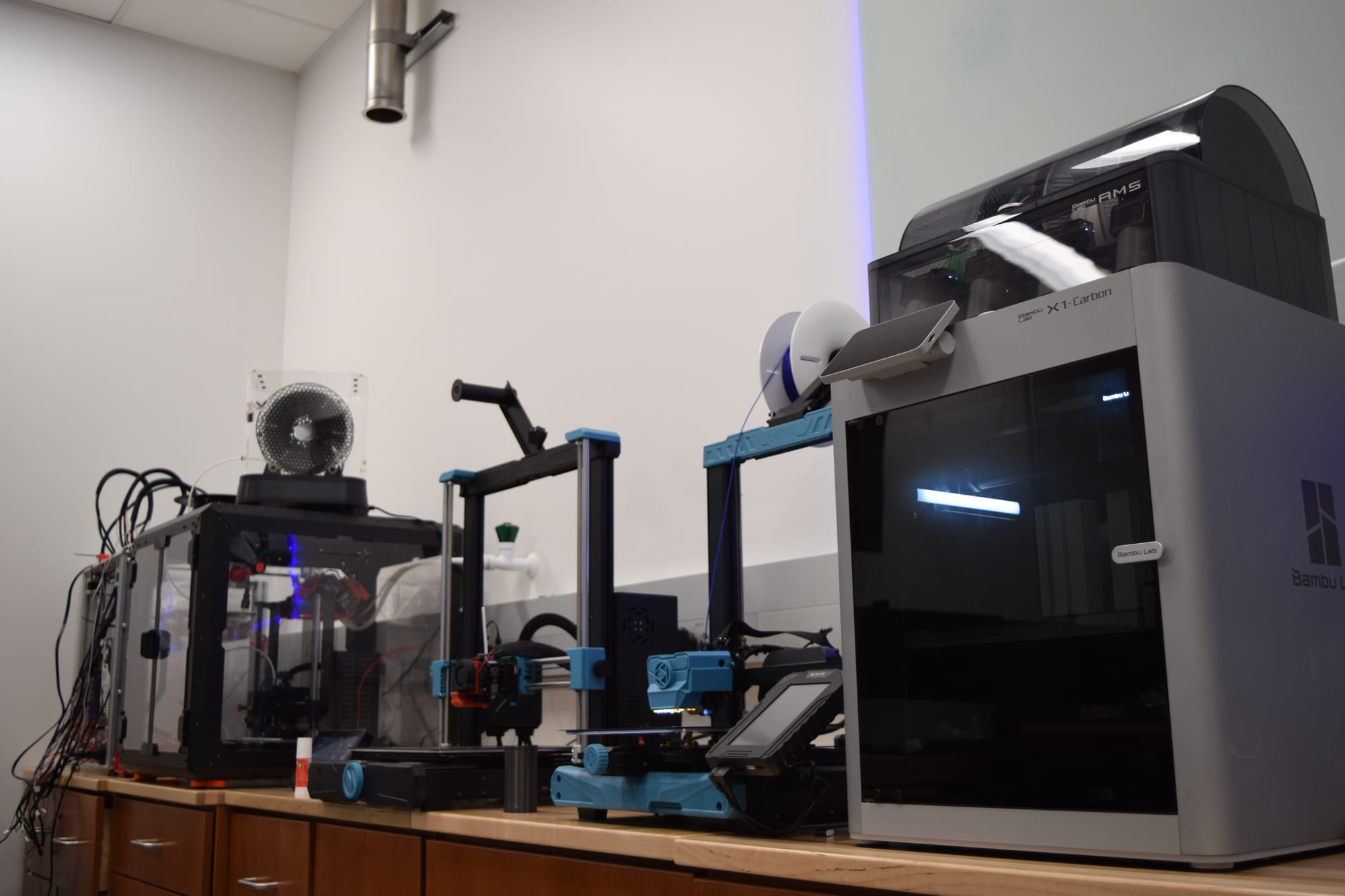

3D Printer Voron Repair

The Voron 2.4 Printer Upgrade project is aimed to enchance the functionality and reliability of the printer by addressing key issues such as outdated toolheads, messy wiring, and disorganized Klipper configurations. The team is upgrading the printer with a Stealthburner Toolhead for improved cooling, easy nozzle changes and better performance overall. The installation of Voron Tap and a dedicated toolhead PCB allows for simplified toolhead maintenance and wiring. A filament runout sensor and macro is an addition to ensure seamless printing. With a complete firmware overhaul and a clean, organized setup, the project significantly boosted the printer’s efficiency and ease of use, making it more reliable for future print jobs.

We are now focused on developing a custom 3D printer capable of reliably printing large polycarbonate and nylon parts. The printer will be equipped with a Voron Dragon Burner toolhead for high-speed printing and excellent part cooling, combined with a Sherpa mini CNC extruder for a compact and efficient filament feed. An E3D PZ Probe will be installed for precise bed leveling and Z-offset adjustments. The system will be powered by a BTT Manta mainboard and Pad 7 for smooth control and a fresh installation of Klipper firmware. High-temperature considerations, such as printing parts with polycarbonate, insulating the chamber, and potentially incorporating active heating, will be addressed after achieving stable operation with PLA. The team also plans to explore adding a filament runout sensor and Nevermore air filter for better print reliability and air quality. This build lays the foundation for future upgrades, including those necessary for printing in high-temperature conditions.